Research Capabilities

Leveraging the above facilities, the group has developed the following capabilities:

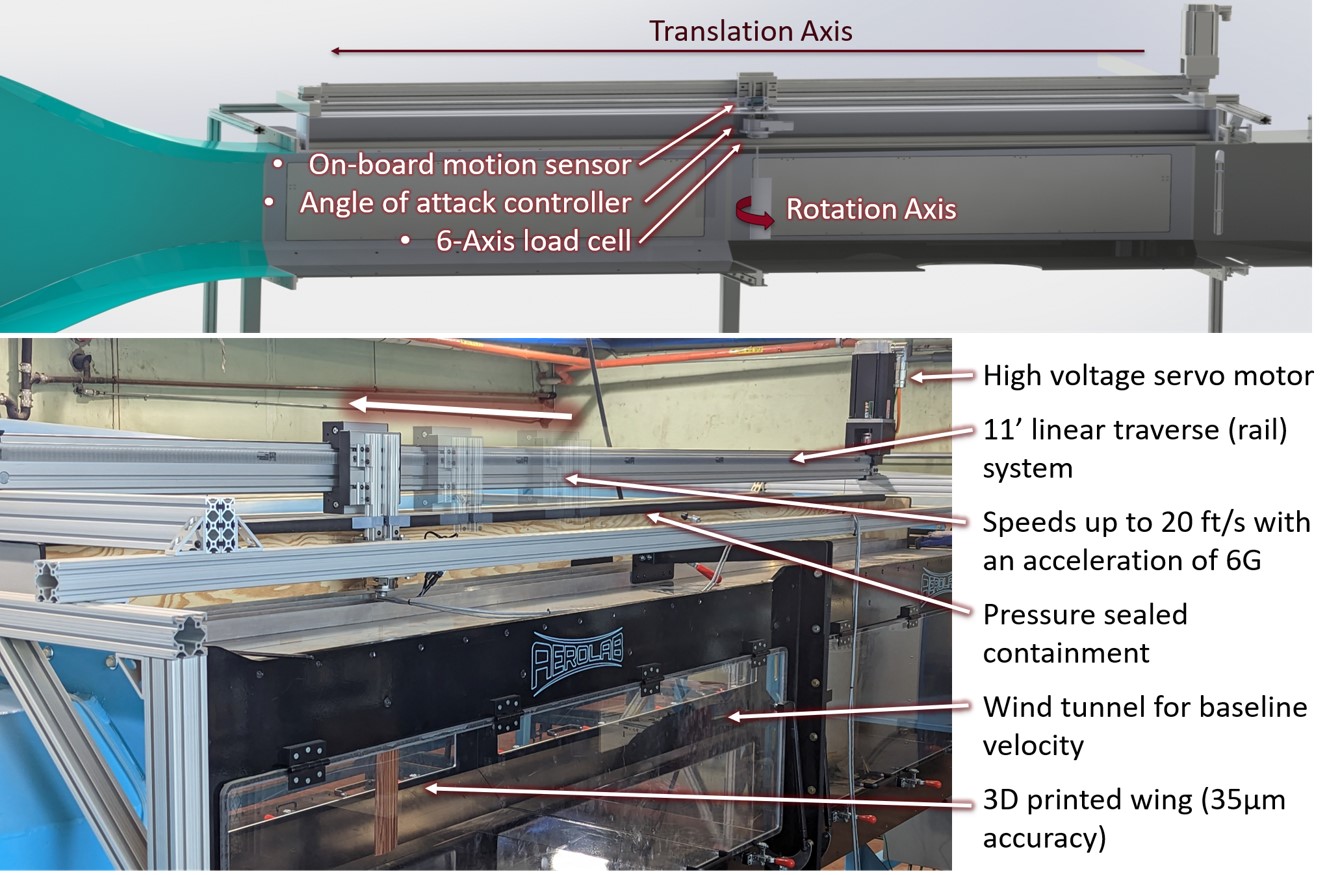

Reverse Wind Tunnel System

Leveraging the 13.3-feet test section of the low-speed, low-turbulence wind tunnel, a high-speed linear rail system capable of accelerating a model up to 6Gs and 20 ft/s across the entire length of the test section has been developed. The system allows us to test in steady and unsteady conditions, with and without flow established by the wind tunnel, thereby enabling a multitude of phenomena to be investigated, including but not restricted to lifting-surface aerodynamics in time-dependent flows, transitional flight mode, and ground effect.

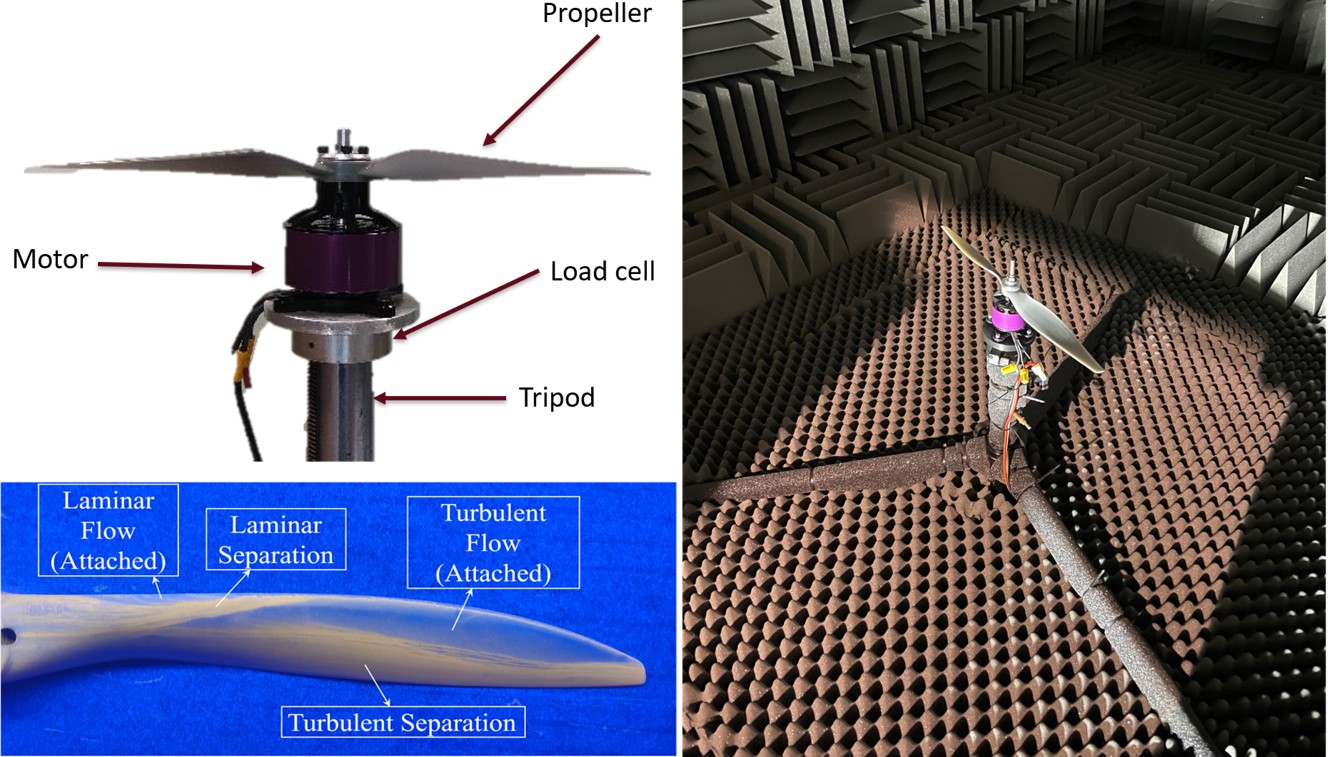

Propeller Design and Characterization

Our group has the capability to design, manufacture, and fully characterize low-speed propellers (up to 21 inches in diameter). Propeller manufacturing is carried out using our filament or resin printers, depending on size and desired surface quality. Propeller performance (static and dynamic), boundary layer behavior, and noise metrics are conducted using a 6-axis load rig, oil flow visualization, and an anechoic test stand, respectively.

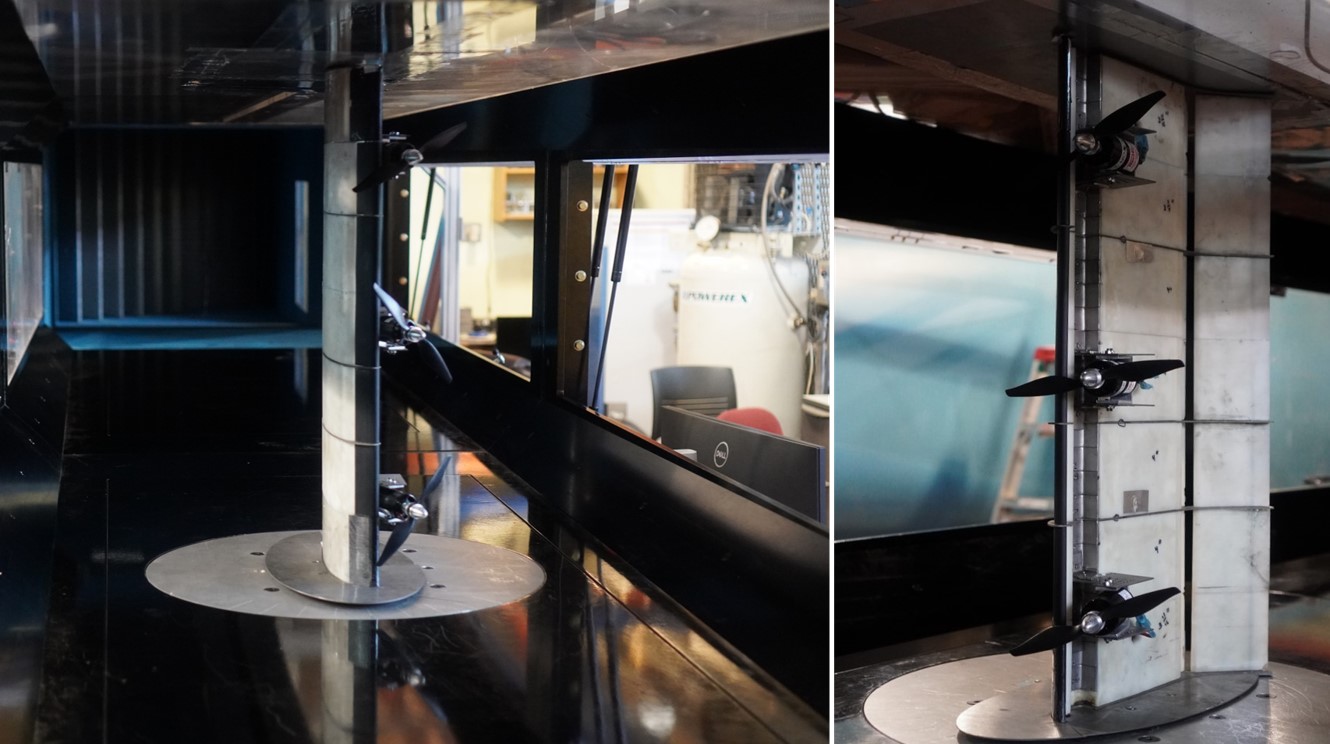

Propeller-Wing Testing

A specialized test rig to experimentally investigate the interactive aerodynamics of 2D and 3D propeller-wing systems (single and multiple propeller configurations) has been developed. Models and associated components are manufactured in-house using our 3D-printing and machine shop facilities. Techniques have been developed to simultaneously run multiple propellers at set RPMS and maintain the same, independent of incoming flow velocity. Combinations of miniature and large force/torque sensors are used to independently measure propeller and wing loading. Surface pressure measurements are made using either pressure tapped models or surface-mounted pressure sensors.

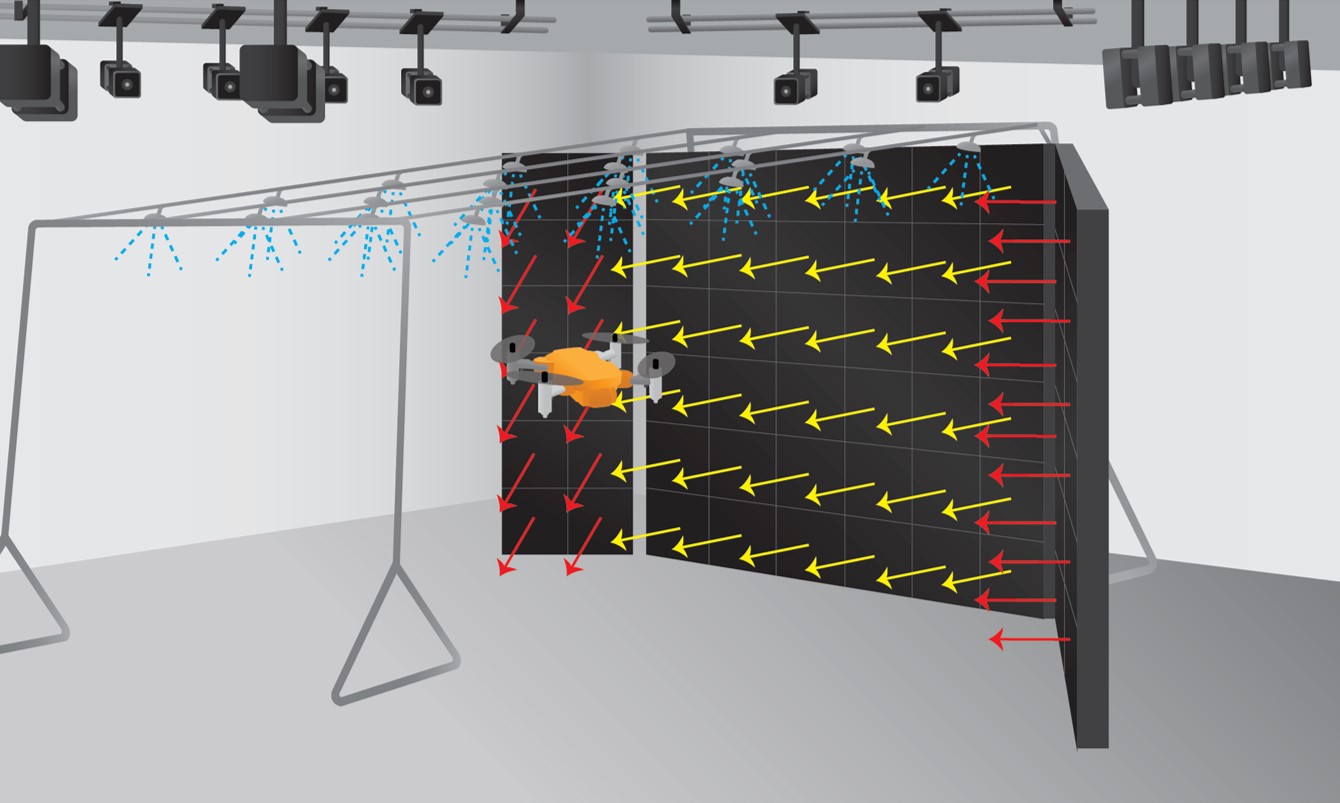

Adverse Weather System

Located at Raspet Flight Research Labs, the adverse weather system comprises of a wind wall with a total of 2,592 individual fans capable of generating uniform and non-uniform wind profiles in a 10-ft x 10-ft x 15-ft (height x width x length) volume. The wind wall is integrated with the motion capture cameras and allows for both fixed and free flight testing. A fast-response 5-hole wind probe is also available to check flow quality and consistency across the test volume. Current expansion plans are focused on including arrays of water sprays to allow for testing in precipitation conditions.